PCB Reliability and Repeatability

In AV Elecauto we follow on our commitments to customers worldwide!

In AV Elecauto we follow on our commitments to customers worldwide!

Our main intent is to prerequisite simplicity in our PCB manufacturing and assembly undertakings. The reason for our coherence in our functions and foundations is a high level of team work and synergy. Our reliability and consistency allows us to take chances with cornerstone to deliver high facet of constituents and design with reliable fabrication and PCB assembly services to our customers. We earmark to render our expert PCB services with succession in time and coexistence in space.

This doctrine of repeatability helps us to achieve the peak position in delivering the services with the best quality assurance and high yield for our customers. Our intentions are to be conscious of each and every step we take in the manufacturing process. The result of our caliber and repeatability in our manufacturing processes can be enlisted below:

- The processes can be measured easily.

- The technologists can then detect the exact problems occurring in the manufacturing of PCB's.

- With this the expert team can take corrective actions to improve and minimize the problems addressed in the process.

Instances:

There are varied defects which do not show us the faults like insufficient or immoderate solder, misaligned components, open power pins and marginal joints. In this case we would go for 'Thermal Profiling' as it attributes temperatures in a solder reflow oven at different zones located on top and bottom of the oven. With this we would discover what temperature profile will work best for PCB's complexities and construction.

There are varied defects which do not show us the faults like insufficient or immoderate solder, misaligned components, open power pins and marginal joints. In this case we would go for 'Thermal Profiling' as it attributes temperatures in a solder reflow oven at different zones located on top and bottom of the oven. With this we would discover what temperature profile will work best for PCB's complexities and construction.

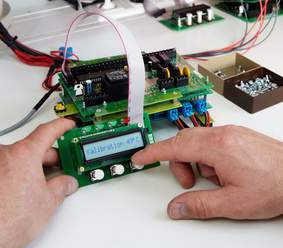

To solve the problems pertaining to low volume and highly complex assemblies, we acute 'Flying Probe Testing'. This helps us detect the missing components and validate the component placement.

To proceed with the high volume production of mature products, 'ICT Testing' is an apt solution. This will assist us to check the resistance and voltage levels at different nodes of the board by running a power signal. 'ICT Testing' is eminent at detecting parametric failures, PCB design-related faults, and component failures.

To proceed with the high volume production of mature products, 'ICT Testing' is an apt solution. This will assist us to check the resistance and voltage levels at different nodes of the board by running a power signal. 'ICT Testing' is eminent at detecting parametric failures, PCB design-related faults, and component failures.

To authenticate the board operations and behavior we use 'Functional Testing'. This helps us to detect the faulty or wrong component values, functional and parametric failures.

The strategies adopted for Reliability and Repeatability in our PCB assembly process have fortuned us with reduced production losses, employee safety, process stability, extended equipment life, Reduction in environmental issues and optimum usage of spare parts inventories.